Gas Reducing Device

✔ “Emergency Diesel Generator” Blind spot of for managing large quantity of fine dust sources

- Even though large quantity of exhaust gas and air pollution sources are discharged during generator operation,

it is free of air pollution regulation

✔ Not only is it becoming the cause of environment pollution by discharging air pollution sources, it is the subject of misled reportof fire and various civil complaints

| Classification | Natural Regenerative Method | Compulsory Regenerative Method |

Complex Method | Note | |||

|---|---|---|---|---|---|---|---|

| DOC | DPF | DOC+DPF | Filter Replacement Type | Electric Heater+DPF | Electric Heater+DOC+DPF | ||

| Structure | Catalyst | Filter | Catalyst+Filter | Catalyst+Filter | Electric Heater+Filter | Electric Heater+Catalyst+Filter | |

| CO | Over 90% | Less than 5% | Over 90% | Over 90% | Less than 5% | Over 90% | |

| HC | Over 85% | Less than 5% | Over 85% | Over 85% | Less than 5% | Over 85% | |

| Nox | Less than 5% | Less than 5% | Less than 5% | Less than 5% | Less than 5% | Less than 5% | |

| Exhaust Gas(PM) | Less than 5% | Over 90% | Over 90% | Over 90% | Over 90% | Over 90% | |

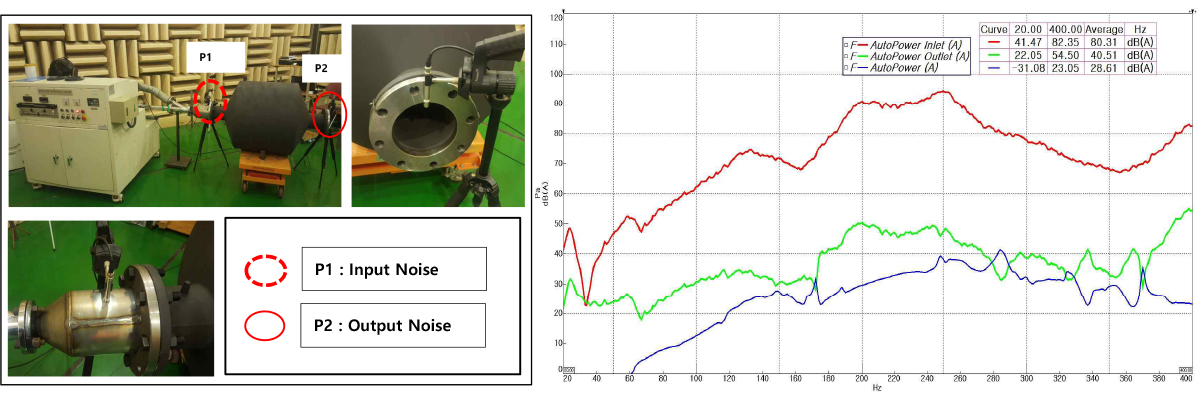

| Noise Reduction | 5dB | 10-20dB | 10-20dB | 10-20dB | 10-20dB | 10-20dB | |

| Environment Protection Law | Not Satisfied | Satisfied | Satisfied | Satisfied | Satisfied | Satisfied | |

| Ringelmenn Smoke Chart | 7~8 | Below 1 Degree | Below 1 Degree | Below 1 Degree | Below 1 Degree | Below 1 Degree | |

| Regenerative Method | None | Cleaning | Natural Regenerative Method (Generator Load Operation) |

Compulsory Regenerative Method | Natural and Compulsory Complex Method | ||

| Material | Ceramic/Metal | Ceramic / Meta l/ SIC | |||||

| Usage | For Emergency Generator | ||||||

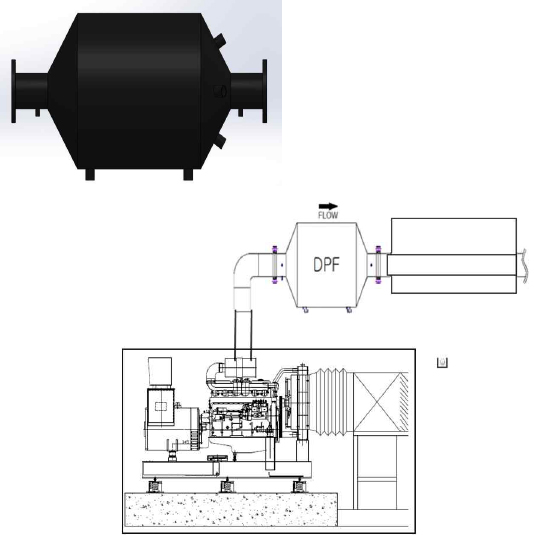

DPF TYPE ▸ DPF(Diesel Particulate Filter) Particulate substances (exhaust gas), which are toxic substances discharged from the engine, are reduced while passing through the filter ▸ Performance Reduction function over 90% of exhaust gas(PM) ▸ Applied Subject Engine Output 90KW ~ 3,000KW ▸ Matters to Attend to If it becomes 80% of the allowed engine back pressure, regeneration and cleaning are necessary

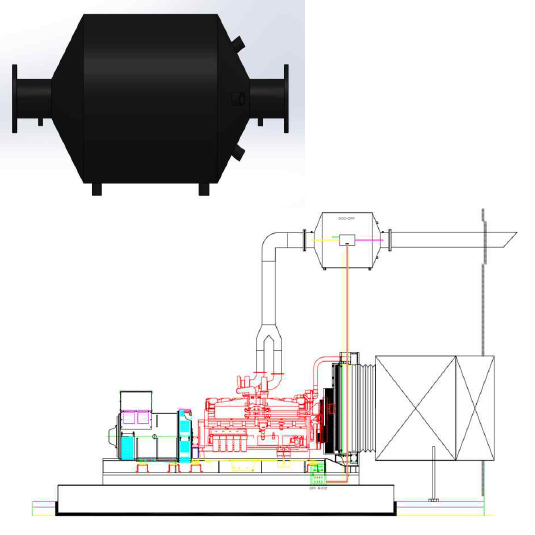

DOC+DPF Type ▸ DOC(Diesel Oxidation Catalyst) It reduces CO, HC which are toxic substances dhscharged from the engine ▸ DPF(Diesel Particulate Filter) Particulate substances (exhaust gas), which are toxic substances discharged from the engine, are reduced while passing through the filter ▸ Performance HC over 80%, CO over 90%, and exhaust gas (PM) over 90% are reduced ▸ Matters to Attend to If it becomes 80% of the allowed engine back pressure, regeneration and cleaning are necessary

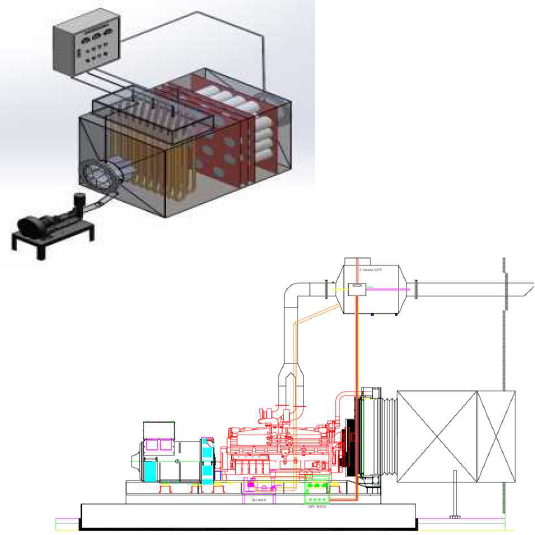

Heater+DPF Type ▸ Electric Heater System Heat is delivered to DPF using the air coming out from the blower by raising the temperature above 550℃ ▸ DPF(Diesel Particulate Filter) Particulate substances (exhaust gas), which are toxic substances discharged from the engine, are reduced while passing through the filter ▸ Performance Reduction function over 90% of exhaust gas(PM) ▸ Matters to Attend to If it is over 40mbar during non-load operation and over 60mbar during load operation, it must be regenerated for 4 hours under 500℃ using an electric heater when the generator is in stopped state

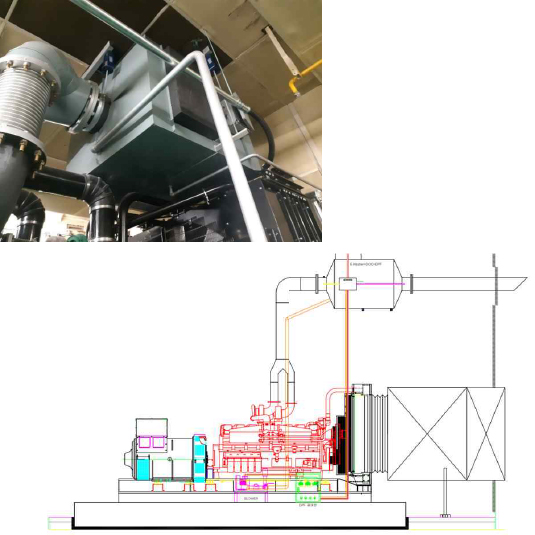

Heater+DOC+DPF Type ▸ Electric Heater System Heat is delivered to DPF using the air coming out from the blower by raising the temperature above 550℃ ▸ DOC(Diesel Oxidation Catalyst) It reduces CO, HC which are toxic substances dhscharged from the engine ▸ DPF(Diesel Particulate Filter) Particulate substances (exhaust gas), which are toxic substances discharged from the engine, are reduced while passing through the filter ▸ feature Natural regeneration is possible from DOC during commercialization or peak control and it is semi-permanent with the complex regeneration method possible of compulsory regeneration using an electric heater at the time of emergency use, and it has good efficiency and it is safe

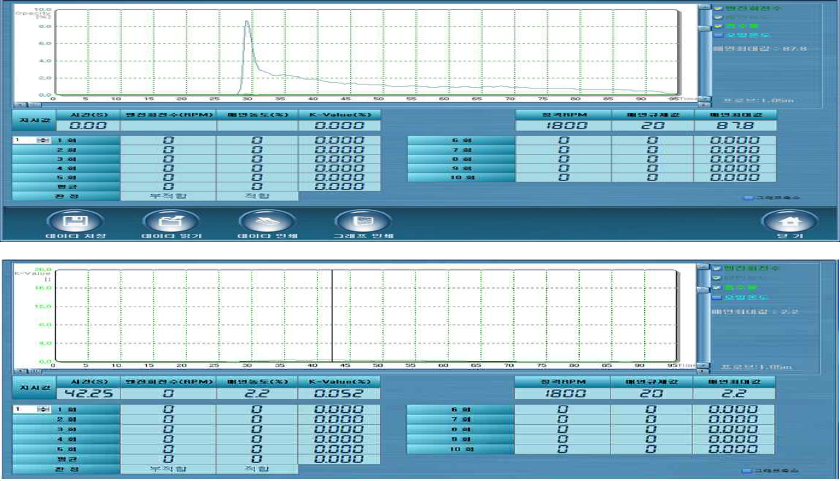

| Classification | Test Results(%) | Standards | Judgment | Note | ||

|---|---|---|---|---|---|---|

| Before Installation | After Installation | Reduction Rate | ||||

| Exhaust Gas | 87.8 | 2.2 | 97.4 | Over 90% | OK | |

Copyright ⓒ 2021 GB ENERGY Co., Ltd. All rights reserved.